I recently received a distress call from a repair garage on a 2019 Jeep Grand Cherokee

where something in their bay went drastically wrong. The vehicle in question was a “Waiter” and the customer was in the office spending part of their day to have some preventative maintenance done to their vehicle. It’s bad enough that you have to deal with all types of diagnostic dilemmas that enter your working bay, but when you create the problem yourself it becomes a chase to the finish line to correct the issue at hand before the owner of the vehicle finds out. I am sure that we have all been down this road at one time or another in our long history of working on so many vehicles with the daily distractions we are exposed to. It helps us to condition ourselves to never take the same path again.

The shop tech was trying to scan this vehicle to do a simple health check to make sure all was good during a routine maintenance service. He noticed some error codes stored in a few controllers so he decided to clear them out. He was fully aware that this truck was a “Cyber Protected” vehicle that required a special cable for his scan tool to perform any bi-directional commands. The manufacturer of his scan tool provided a warning screen on this particular vehicle to alert him that he needed to use the special cable if he was not just scanning the vehicle, but needed to do code clearing or any other bi-directional procedures such as calibrating sensors, bleeding brakes or activating relays and solenoids. The scan tool also provided him with a picture for the hookup location.

He had used the adapter cable many times before, but when he went to use it this time it did not function properly and he ended up with an inoperative front center panel display once he reassembled the center dash panel. At this point, he felt that he had shorted something out, so this is where he called me in for technical assistance while I was still in his area that morning.

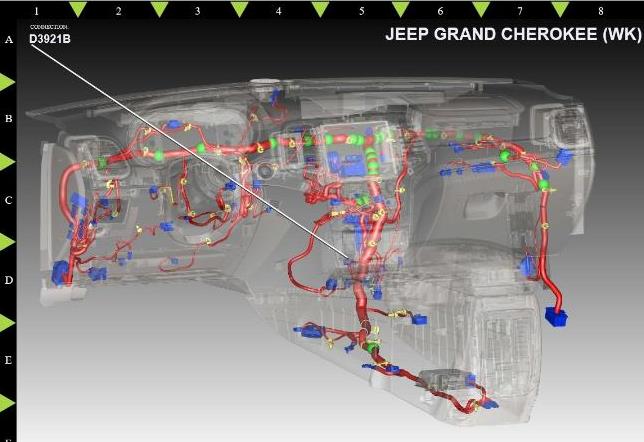

When I arrived at the scene, I entered the shop through the garage door rather than through the office where the customer was waiting. I needed to do this job in stealth mode so as not to draw any attention to the problem at hand. The shop tech removed the upper part up the center dash to show me his procedure to access the Gateway Control Module to install a bypass cable into its harness connectors. Basically, you were supposed to unplug both Gateway Module connectors and plug them into this “Y-Cable” adapter and then hook the main part of the cable to the scan tool. The problem here was the module only had one of the connectors he was used to plugging into, but the second connector in the module was much larger

When he looked around in the same area he noticed a second connector that would fit the scan tool adapter and plugged it in

This was when all hell broke loose.

It turns out that this second connector was a feed cable for the front display panel, and it was shaped in just the right dimension to accommodate the Y-Cable. When this was done, the fuse blew in the engine compartment fuse box to protect the panel’s circuit that was exposed to a direct path to ground from the Y-Cable. The module he was plugging into was not the Gateway Control Module, but rather the A/C Control Module that was located in the same place that other Chrysler trucks secured a Gateway Control Module. The location of the Gateway Control Module on this particular truck was located in a lower position at the front part of the center console near the base of the center dash.

I could now see how this could easily confuse a scan tool user. The actual cable hookup screen on the scan tool was just a generic picture of the location of the Gateway Control Module that did not apply to all vehicles so it was basically up to the user to find the proper location using their own repair information.

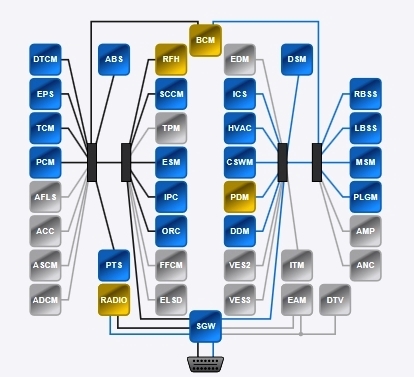

I replaced the blown fuse in the engine compartment and had the tech put the vehicle back together. I proceeded to use my Chrysler Wi-Tech factory scan tool which could command the onboard Gateway Control Module to unlock itself so I could clear out all error codes stored in the network and the shop could finish up the vehicle. If you look at the topology map of this Chrysler vehicle using the Wi-Tech software, you will notice a Secured Gateway Module located in front of the OBD2 connector that controls scan tool communications in and out of the network.

The diagnostic port is normally open for data acquisition, but it is locked for bi-directional acquisition from scan tool commands. Chrysler holds the authority for you to be able to access bi-directional controls, and through their secured server and the proper credentials, the Gateway Control Module will be unlocked without using a by-pass cable that could invite unwanted labor or mishaps.

This all started a few years back when a couple of “friendly hackers” decided to use a late model Jeep to test the vulnerability of onboard CAN networks to hacking possibilities. They were able to hook a laptop to the diagnostic port and analyze communication protocols being transmitted within the network between controllers. Then they were able to mimic these messages, reproduce them and sent commands into the network to perform tasks like shutting down the engine, applying the horn and wipers and even blasting the radio. It was then taken to the next level by hacking into a Bluetoothed phone that was synchronized with the onboard Telematics Control Module, which in turn was tied to the vehicle CAN network. They were successfully able to remote into the phone and send command messages into the CAN network via the Telematics Control Module while they were a distance away from the vehicle. This all sounds like weird science, but it became a reality. They posted it on You-Tube and when Chrysler saw the video they quickly took action to address the issue to prevent any future terroristic opportunities available for the“dangerous hackers of the world”.

The Car Spy Study Act of 2017 was soon implemented by our government to direct the National Highway Traffic Safety Administration to create standards for automakers to address cybersecurity in automobiles. This would cover building firewalls in the onboard networks to prevent drivetrain access from the Telematics Control Module. They would also require encrypting language within the networks to prevent easy hacking of shared onboard messaging between controllers. This was soon followed by Chrysler deciding to install a Secured Gateway in front of the OBD2 connector on late model 2018 vehicles and newer to prevent unauthorized access for bi-directional manipulation. The fear is if this is not addressed early then it would hurt the automotive industry’s plans to move full speed ahead in producing Level 3 to Level 5 driverless cars in the close future.

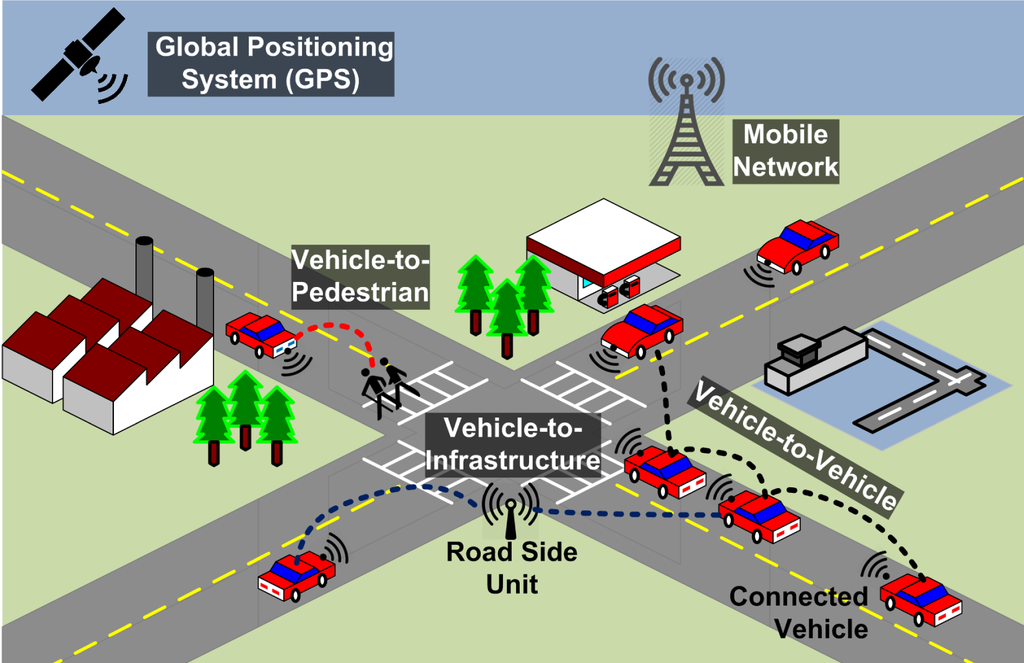

Aftermarket scan tool companies are now slowly migrating to push for wireless access scan tools to link to a secured website where each repair shop will have to register their scan tool along with the names of individuals in the shop and complete a shop information form. These websites will be working closely with manufacturers and the federal government to allow a registered scan tool the ability to unlock a secured vehicle Gateway Control Module. The manufactures will now be able to monitor all activity on the vehicles and see who is accessing them and what is being commanded within the vehicle network. This will be the new norm of the vehicle industry and will create an atmosphere never seen before. It’s all about driver security for what is to come. If we are looking to link vehicles to a closely linked network of other vehicles and traffic infrastructures, it is a critical step that has to be taken. Just imagine vehicles being wired into a world-wide web like our home computers. Vehicles can talk to one another and share their locations before approaching the same intersection.

There would be traffic lights that could send messages to cars that the light is turning red before the vehicle reaches an intersection. Traffic and weather reports can also be sent to vehicles to alter their destination routes. It all sounds so crazy, but we are living in a fast pace of never-ending changing technology.

There are a lot of guys in the field I talk to who will admit that automobiles have gotten out of control and they just want out. Then I pose the question of what they would do when their passion was always about cars. You need to embrace the new technology as it comes into your bay and find ways to retool your business to accommodate the changes. There is no time to sit back and become stale to the industry. The key is to do a lot of research to learn new technology, be involved in continuous education and don’t resist change or it just may push you out of the industry. It is actually the best time right now to get in the business because the diagnostics and services of these new systems could be more lucrative for you.

I’m guessing that by now a lot of you techs out there have moved to register your scan tools with a secured server to unlock the 2018 and newer Chrysler vehicles. Talk to your scan tool dealer for more information because you don’t want to be left out in the cold and loose customers because you’re unwilling to move forward. My only hopes is that this article has inspired you to stay in this business and make newer investments in your shop to keep you going forward.